Nylon teeth zipper is a kind of zipper, which refers to the zipper whose microphone teeth are made of copper, cupronickel or aluminum material. Compared with nylon zipper and resin zipper, it is stronger and more expensive. It is mostly used in jeans, jackets and backpacks. superior. Nylon zipper is composed of nylon monofilament wrapped around the center line through a heating die. It has low cost, large output and high popularity. It is currently a popular zipper in the market. The raw materials are mainly polyester monofilament, central core wire, polyester processing yarn, suture, zinc alloy of slider, engineering plastic, etc.;

Introduction

Nylon zipper is a connecting piece that relies on the continuous arrangement of elements to combine or separate items, and is now widely used in clothing, bags, tents, etc.

1. A fastener consisting of a row of metal teeth or plastic teeth on each of the two belts is used to connect the edge of the opening (such as the mouth of a garment or a bag), and a slider can pull the two rows of teeth into the interlocking position to close the opening ;

2. A chain attached to something (as an object to be lifted or dropped) to tighten, stabilize or guide it.

Nylon zipper assembly

1. Tape is a flexible tape woven from cotton yarn, chemical fiber or mixed chemical fiber, which is used to carry fastener elements and other zipper components;

2. The edge of the ribbed bead tape is used to carry the reinforcing part of the metal or plastic elements;

3. Rib rope rope refers to a rope-like object composed of multiple fibers in the middle of the rib;

4. Chain element scoops refers to the teeth of a certain shape after processing of metal, plastic and other materials;

5. Filler cord is made of multi-strand fiber threads and is used for the production of nylon zipper stringers;

6. The tooth chain refers to the continuous arrangement of teeth;

7. The one side zipper chain is fixed on the cloth belt and called the chain belt;

8. The chain belt zipper chain is formed by the meshing of the two sides of the tooth chain belt;

9. The top stop is fixed on the fastener chain to prevent the slider from sliding out of the fastener chain when the fastener chain is pulled together;

10. The bottom stop is fixed on the fastener chain to prevent the slider from sliding out of the fastener chain when the fastener chain is opened, and a stopper that prevents the fasteners on both sides from being completely separated;

11. Back & forth head tape The tape without the element part on the zipper is called the head, the upper end is the front head, and the lower end is the rear head;

12. The cannula (also called the pin) pin separable is fixed at the end of the open-end zipper and is used to completely separate the tubular piece of the chain;

13. The socket box retainer is fixed at the end of the open-end zipper to completely separate the square pieces of the chain;

14. Two pin is a kind of tube-shaped stopper on the double-opening zipper that cooperates with the intubation tube;

15. Strengthened tape strengthened tape is a composite sheet used to enhance the bonding strength of cannula, socket and cloth tape and improve the service life of zipper;

16. The slider is a moving part that engages and pulls apart the elements;

17. The puller is a component of the slider. It can be designed to be connected with the slider body in various geometric shapes or connected with the slider body through the middle piece to realize the opening and closing of the zipper;

18. The connecter is the intermediate element connecting the slider body and the pull tab;

Classification

The mouth height of the slider is 2.6-2.7MM, the mouth width is 4.75-4.85, the combined width is 4.55±0.05, and the thickness is 2.4±0.05

Closed tail: When pressing the upper and lower ends, the temperature, injection delay time, and pressure holding time should be adjusted properly. If the size of the closed-end zipper is about 15CM, if there is a certain number, one row of microphones and two belts can be used. The same is true. , if there is a suitable size and quantity, it can also be one piece.

Open end: When sizing, make sure to take the lead? FONT face="Times New Roman">4.5cm, (17 microphones), the pattern of the ultrasonic tape is clear, the left and right are uniform, and the position is about 1.5mm away from the microphone, and it is guaranteed to hit Hole crochet hooks firmly and punches through.

Press adjustment: the high pressure should not exceed 100kg/cm2, the injection pressure should be 40kg/cm2, the holding pressure should be 30kg/cm2, the low pressure should be below 10kg/cm2, and the cooling time of high pressure and pressure holding should be more than 0.1 seconds. ) and then adjust.

Factors that are prone to defective products: exposed shin (the reason is whether the upper and lower mold positioning pins are broken and whether it is appropriate), the latch is falling off (whether the injection pressure is appropriate, whether the holding pressure and cooling time are sufficient), and the square cloth seam is narrowed (the pressed zipper needs to be cooled down) Then wear the slider)

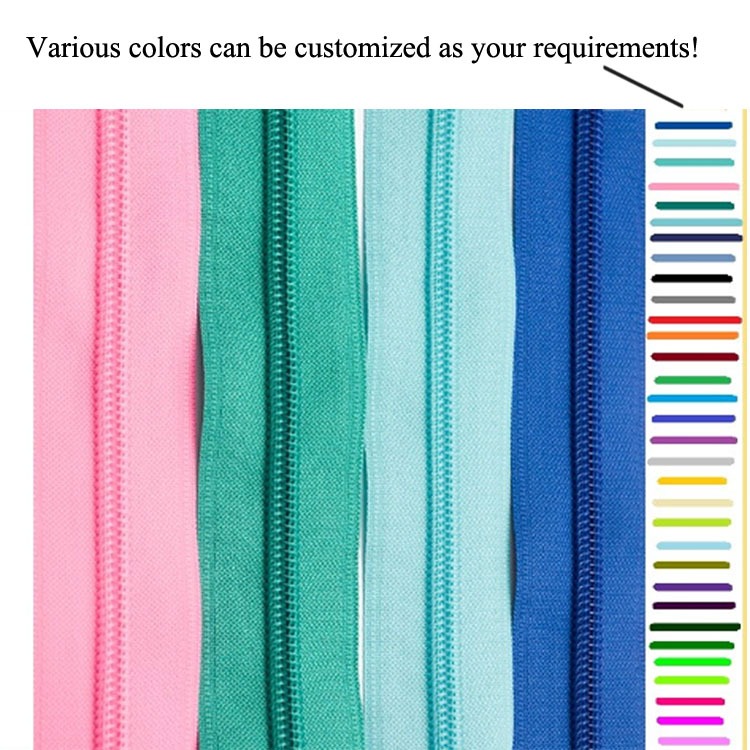

Nylon zipper options

Tape: Since the raw material of the metal zipper tape is composed of different types of silk threads such as polyester thread, suture thread, central thread, etc., its weight and coloring are different, so it is easy to produce color difference on the same zipper. When selecting the tapes, the dyeing should be uniform and there is no turbid point. The tapes made of different fabrics are mainly soft to the touch.

Micro teeth: The microphone teeth of metal zippers are also electroplated and colored, so when purchasing, you must pay attention to whether the surface is evenly plated, whether there is any color flower phenomenon, and whether it is smooth when pulling the zipper up and down. Dongguan Yifeng Zipper Factory warmly reminds that after the zipper is pulled, it is necessary to observe whether the left and right teeth are engaged with each other. Asymmetric zipper teeth will definitely affect the use of the zipper.

Puller: There are many shapes of metal zipper pullers, and the finished product can be small and delicate, or rough and majestic. But no matter what kind of slider, it is necessary to feel whether the slider can be pulled freely, and whether the zipper cannot be pulled or closed. Now the sliders on the market are equipped with self-locking devices, so after the zipper is pulled, it is necessary to check whether the zipper will slide down after the lower lock is fixed.

Limit code: The upper and lower stops must be tightly fastened to the microphone teeth or clamped on the microphone teeth, and must be strong and perfect

Notice

When washing or processing garments, pay attention to:

1. After the wool knitwear is ironed, make sure that the zipper is fully cooled before packaging. Otherwise, the metal zipper will react with water vapor and easily change color.

2. After processing clothing products, some chemical reagents are easy to remain, and it is easy to react with metal zippers at this time. Therefore, before assembling metal zippers, it is necessary to ensure that the leather has been fully cleaned and neutralized.