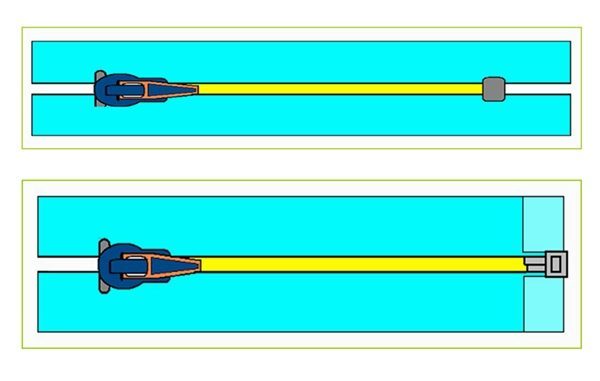

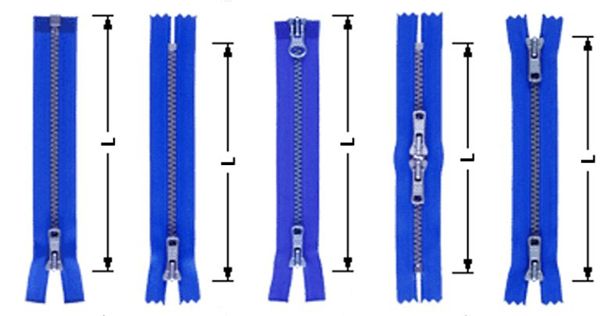

The length of the stainless steel zipper refers to the length of the meshed zipper in the natural flat state, which can be changed according to the actual application. Depending on the zipper form, the concept of zipper length is slightly different.

The length concept of the following different forms of zipper, including open end zipper, closed end zipper, double open end zipper, double closed end zipper.

Open zipper

The length of the open end zipper is from the outer end of the latch to the top of the slider, excluding the tape at the top.

Closed zipper

The length of the closed-end zipper is from the outer end of the bottom end to the top of the slider, excluding the top and bottom tapes.

Double-ended zipper

The length of the double-ended zipper is from the top of the top puller to the top of the bottom puller.

Double closed end zipper

Double-ended closed-end zippers can be divided into X-type and O-type, each with 2 sliders. The difference is that the length of the X-shaped double-ended closed-end zipper is from the top of the upper slider to the top of the lower slider. The length of the O-shaped double-ended closed tail zipper is from the outer end of the bottom end to the outer end of the other bottom end.

allowable tolerance

During the production process of the zipper, there will be natural tolerances due to mechanical speed, process conditions and chain tension, and the longer the zipper length, the greater the tolerance.